Cleaner

Body Introduction

Parts

Introduction:

A: Battery Pack.

B: Cleaning Button.

C:

Adapter Sleeve outside, Rotation Axis inside.

D: Lead-in

adapter, help the alignment of cleaning bar against the fiber

end-face.

Cleaner Installation:Break off the

cleaner body, Put the batteries into it as electrode symbol

suggested inside. Please be sure that part B is properly connected

with part A where the carved “on” on part B1 is against

the trail on

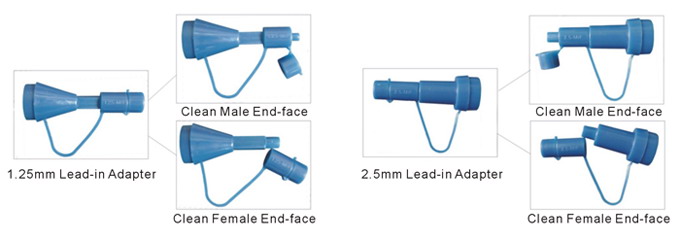

KDV-137 Lead-in Adapters

Not

only have three types of adapters, covering all the cleaning modes,

KDV-137 also concentrate different functions(one Lead-in adapter can

clean both male and female type), distinguished from the traditional

tools, bringing you a complete convenience for operating.

KDV-137

Cleaning MaterialsTypes:

There

are two types of Cleaning Materials: KDV-F25 / KDV-F15

The

materials from the front-end of stick are 0.5~0.8mm thick, madding

from imported high-density glabrous fiber. It rotates with stick 80

transfer per second, sucking all the contamination from the end-face

just within 3~5 s. No breakage, no slag, consecutive cleaning of 20

faces per stick even contribute to no repeated pollution, but please

note that consecutive cleaning of 50 faces per stick may relatively

weaken the performance.